Powder Coating Process Explained

Learn the complete step-by-step powder coating process including surface preparation, application, and curing methods used by CORRONiL CONTROL for durable industrial finishes.

Setting new standards for durability, performance, and corrosion control across diverse industries worldwide.

CORRONiL CONTROL is a trusted name in industrial surface protection, specializing in high-performance solutions that prevent corrosion and extend the life of critical infrastructure and equipment.

With years of expertise, we provide advanced services including powder coating, epoxy painting, thermal spray metallizing, and rubber lining. Our techniques are designed to withstand harsh industrial environments, chemical exposure, and extreme temperatures — ensuring durability, safety, and reliability for every project.

We proudly serve key sectors such as:

At CORRONiL CONTROL, quality and client satisfaction come first. We use industry-standard procedures, certified materials, and experienced applicators to ensure precise and long-lasting protection. Every project is executed with a commitment to safety, timelines, and performance.

Our Strengths:

Whether it’s a storage tank, pipeline, structural steel, or plant machinery — CORRONiL CONTROL is your reliable partner for premium surface protection that lasts.

Eco-friendly protective finishes with a broad color range, high durability, and long-lasting corrosion resistance.

Efficient surface preparation ensuring optimal adhesion and a smooth, professional finish.

Heavy-duty coatings that provide extreme corrosion resistance and durability in harsh environments.

Long-term protection for steel and iron structures with high-temperature and wear-resistant coatings.

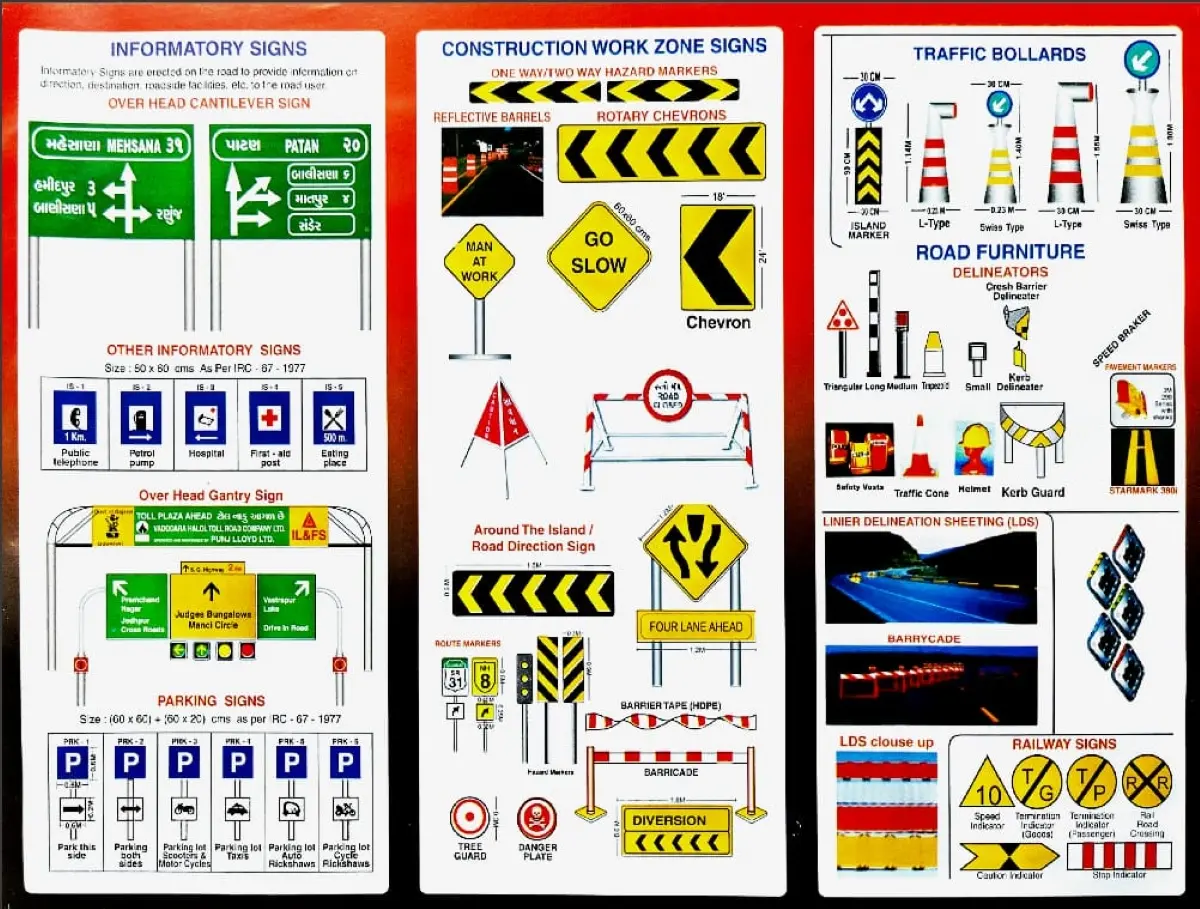

Custom Sign Boards including Flex, Aluminium 2D, and Multicolor Promotional SS Sign Boards.

Protective linings for tanks and pipelines designed to minimize wear and maximize lifespan.

Designed and installed for Stee Art Pvt. Ltd. using precision-engineered fabrication and corrosion-resistant coatings.

Completed for MilkPro Industries with hot-dip galvanizing for pipelines, equipment, and structural steel.

Massive storage tanks protected for ONGC Offshore Projects with epoxy and metallized coatings.

Executed for ChemTech Ltd. with dual-layer epoxy coatings ensuring extreme chemical resistance.

Components treated with a 3-coat system: zinc primer, epoxy mid-coat, and polyurethane topcoat for long-term protection.

Coated over 10,000 meters of high-pressure piping with heat- and abrasion-resistant linings for optimal performance.

"The dedication and quality provided by CORRONiL CONTROL have significantly improved the longevity and reliability of our equipment. Their professionalism is unmatched."

"Working with CORRONiL CONTROL was a seamless experience. Their technical knowledge and service execution are among the best in the industry."

"CORRONiL CONTROL provided exceptional support for our industrial projects, delivering timely solutions and unmatched quality."

Common questions about our industrial coating and surface protection services.

Powder coating provides a durable, corrosion-resistant, and eco-friendly finish with low maintenance and excellent longevity, making it ideal for industrial machinery, pipelines, and structural components.

Sand blasting is used to prepare surfaces by removing rust, old coatings, and contaminants. It ensures proper adhesion of coatings and creates a smooth, even finish for maximum durability.

Yes, CORRONiL CONTROL offers both on-site and off-site services depending on project requirements, access, and client preferences.

We serve oil & gas, power, pharma, manufacturing, food processing, water treatment, and heavy engineering industries across India.

Yes, our coatings are applied using certified materials and professional techniques, and we provide warranties depending on the type of service and project scope.

Stay informed with the latest trends, expert tips, and case studies on industrial coatings and surface protection.

Learn the complete step-by-step powder coating process including surface preparation, application, and curing methods used by CORRONiL CONTROL for durable industrial finishes.

Discover how CORRONiL CONTROL uses sand blasting to enhance coating adhesion, extend equipment life, and prepare surfaces for high-performance industrial coatings.

Reach out for inquiries, quotes, or more information about our solutions.

Address: Plot No. 1/A, Sadbhav Industrial Park, Vibhag-2, Undrel Road, Dhamatvan, Ta. Daskroi, Dist. Ahmedabad-382435.

Phone: +91 98250 73281, +91 87995 95305

Email: c.control2005@gmail.com

Business Hours: Mon-Fri: 9 AM - 6 PM | Sat: 9 AM - 1 PM